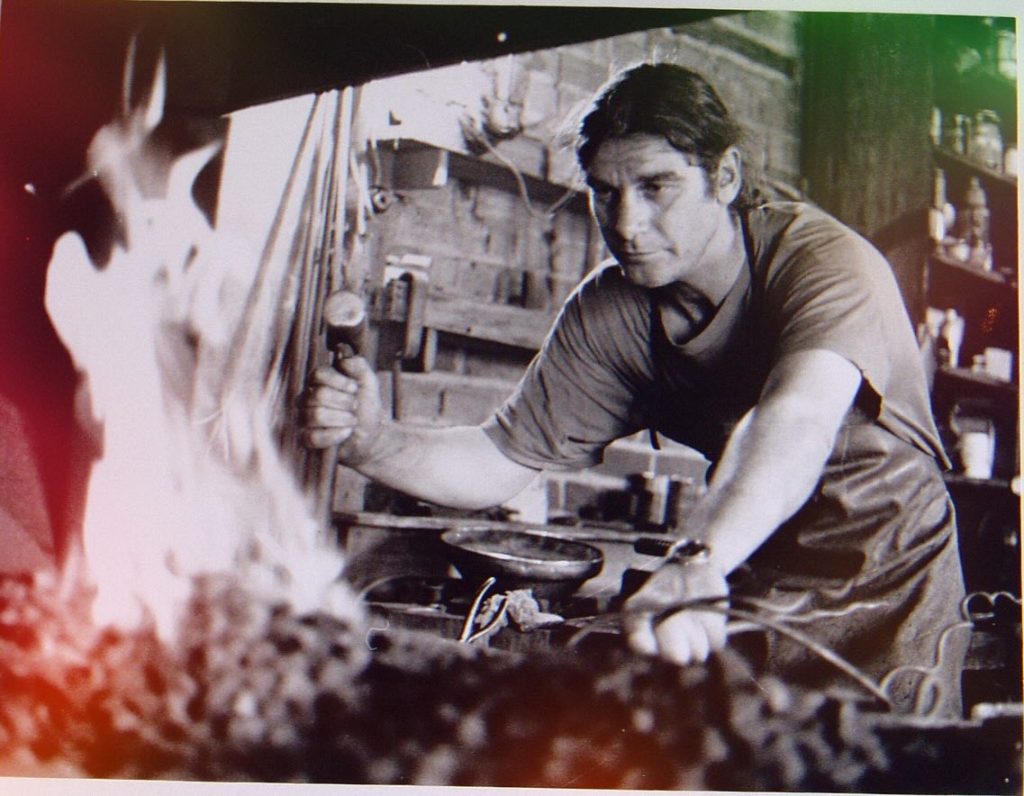

THE BLACKSMITH’S FIRE..

Down through the years, Individual blacksmiths have shared there own acquired knowledge all sorts of techniques for various processes.. fire welding, hardening, tempering, forging a square bend..the list is very long with many tangents and forays into what borders on the magical arts (what isn’t understood is attributed to magic and may require the petitioning of relevant Gods).

All said then, there are steps taken to achieve various ends and they may become fixed and evolve into rituals, and then gods forbid that you transgress, or you might earn the dreaded shake-of-the-head of the visiting master smith.

So, without trepidation, confident in my magical arts, I hereby describe, in plain language….

THE ART OF THE BLACKSMITH’S FIRE

Taking 6’ x 2 1/2” diameter round section of tree branch, place it upright on the tyeure, (this is the grate on the bottom of the fire through which the air is forced, and using a good bituminous coal, pea-sized to jellybean.. firmly packed around this plug of wood to nearly the height of it and extending around it to at least a 10” diameter.. dampen all with a tin can (beans or apricot jam) sprinkler,(14 holes in the bottom) on a decently long handle of iron, with water from your slack-tub or barrel.. packing firmly all the while, using your a slice.. (a heavy, 5” x 5”x 1/4, sharpened, square iron shovel head, fire-welded to a yard-long, iron handle with a circular hand grip).

Next.. remove the wooden plug and kindle a fire in the (magical) space revealed, with crumpled paper, (preferably from some Murdoch rag, pilfered from a café table, preventing any ignorant gitt from reading it).. adding some thin sticks and or wood shavings and ignite.

Once this little fire has caught, ..from the previous day’s saved charcoal, add a couple of handfuls and proceed to boil your billy for your cup of tea.

Next, cup of tea in hand, scribble your intended design, 1:1 scale, for the work intended, on the floor beside the anvil, with chalk, all the while adding a little more charcoal and placing the iron for your intended project. on the heat…

The rest, then, is another story and a gorgons knot of equal parts of invention, lies, concentration and mighty effort, woven skilfully into a forged fabrication.

The dampened coal prevents the bituminous coal from smoking too much and allows it to fuse (magically) with itself , while undergoing the process of “coking” and forming a solid do-nut shaped ring around your fire. It is important to keep dampening the coal/coke, all the while adding the previous day’s saved coke to the central fire to facilitate heating your progressing forged project.

Now.. at tea time or lunch.. shut down the draft, allow the fire to cool sufficiently to lift out the cooked, coked donut, (that has grown the full 10” diameter) and break this up for your afternoon’s fuel.. remake your fire then, while eating your cheese and bringel (?,eggplant or aubergine) pickle sandwich and boiling your Billy…while sitting on your anvil and staring around in a satisfied manner.

At days end.. shut down your fire..remove and put aside the fresh coked donut till the morrow.. complete whatever hammer and anvil tapping ritual you have to perform to satisfy your mild and wryly amusing OCD (obsessive compulsive disorder). Mine is a short tune, tapped out on the anvil with two hammers and a florish.

Go home. (or drink beer etc with workshop buddies, then go home).

Next.. preparing the fire for fire-welding.. making a reduced atmosphere oven on the fire, using coal.